We pride ourselves in understanding our customer's needs and specialise in providing custom solutions - whether designing one-off prototype’s or high volume manufacture.

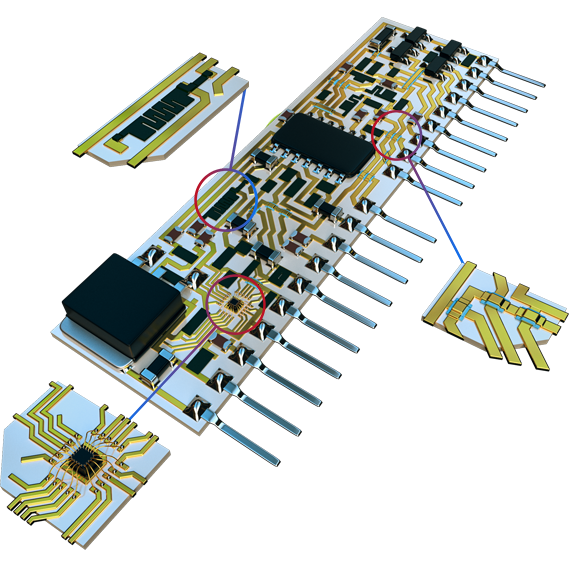

We are a team of creative thinkers and technical engineers passionate about creating great products and solutions for our clients. Using a combination of expertise, heritage and state of the art design tools, we create advanced thickfilm electronics solutions suited to harsh and demanding operating environments.

As New Zealand’s only manufacturer of Thick Film Microcircuits and with 35 years in the electronics industry, we have the capability to design, prototype, evaluate and manufacture custom solutions in our purpose built facility. Where applications require quality, consistency and reliability, we have the creative design solution you need.

Our experience includes, Thick Film [link], RF & Microwave, Data telemetry, Electronic control mechanisms, PCB assembly, PCB modification, Chip & Wire, Electronic packaging, Optoelectronics, hermetic packaging and welding, prototyping and volume manufacture. See case studies for examples of how we’ve used some of these skills to solve our clients challenges.

“Its always refreshing to deal with people and organisations that deliver on their promises.”